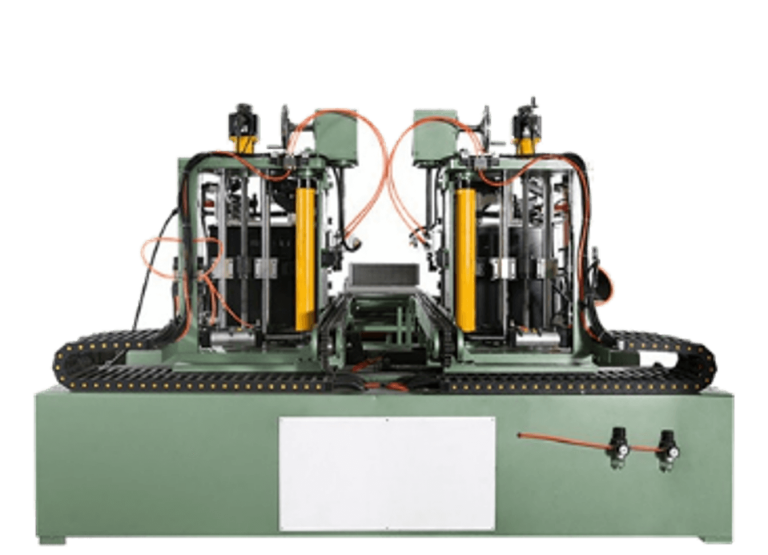

A fully automatic gas-shielded (MIG/MAG) welding machine is used to weld corrugated walls in transformer tanks.

Corrugated walls can be manufactured with a maximum steel thickness of 1.21.5 mm, a width of 3001600 mm, an inner gap of 6-8 mm, a height of 50~400 mm, and a fin spacing of at least 30 mm.

To reinforce the corrugated wall, extra transverse steel rods are welded to both sides of the welded panel.

Sheet Thickness: 0.5-1.75 mm

Fin Length: 300-1,600 mm

Fin Width: 50-400 mm

Fin Spacing: ≥30 mm

Fin Inner Gap: 6-8 mm

Material: 6112 Cold Rolled Steel, SS 316L

Operating Speed: 1-5 fins/min

Capacity: 75 tons/month